| A (mm) | B (mm) | PRICE KEY | WELD METAL | HANDLE CLAMP | MOULD | Quantity | Add To Baskit |

|---|---|---|---|---|---|---|---|

| 16 | 20 x 2 | D | #045 | HCD | MDCB516202 | ||

| 16 | 20 x 3 | D | #045 | HCD | MDCB516203 | ||

| 16 | 25 x 3 | D | #065 | HCD | MDCB516253 | ||

| 25 | 20 x 2 | D | #045 | HCD | MDCB525202 | ||

| 25 | 20 x 3 | D | #045 | HCD | MDCB525203 | ||

| 25 | 25 x 3 | D | #065 | HCD | MDCB525253 | ||

| 35 | 20 x 2 | D | #045 | HCD | MDCB535202 | ||

| 35 | 20 x 3 | D | #045 | HCD | MDCB535203 | ||

| 35 | 25 x 3 | D | #065 | HCD | MDCB535253 | ||

| 50 | 20 x 3 | D | #065 | HCD | MDCB550203 | ||

| 50 | 25 x 2 | D | #065 | HCD | MDCB550252 | ||

| 50 | 25 x 3 | D | #065 | HCD | MDCB550253 | ||

| 70 | 25 x 3 | D | #090 | HCD | MDCB570253 | ||

| 70 | 25 x 4 | D | #115 | HCD | MDCB570254 | ||

| 70 | 25 x 6 | D | #115 | HCD | MDCB570256 | ||

| 95 | 25 x 4 | D | #150 | HCD | MDCB595254 | ||

| 95 | 25 x 5 | D | #150 | HCD | MDCB595255 | ||

| 95 | 25 x 6 | D | #150 | HCD | MDCB595256 | ||

| 120 | 25 x 5 | D | #150 | HCD | MDCB5120255 | ||

| 120 | 25 x 6 | Dr>D | #150 | HCD | MDCB5120256 | ||

| 120 | 30 x 5 | D | #200 | HCD | MDCB5120305 | ||

| 150 | 25 x 6 | D | #200 | HCD | MDCB5150256 | ||

| 150 | 30 x 5 | D | #200 | HCD | MDCB5150305 | ||

| 150 | 40 x 5 | D | #250 | HCD | MDCB5150405 | ||

| 150 | 50 x 6 | E | 2 x #150 | HCE | MECB5150506 | ||

| 185 | 31 x 6 | D | #250 | HCD | MDCB5185316 | ||

| 185 | 40 x 5 | E | #250 | HCE | MECB5185405 | ||

| 185 | 50 x 5 | E | 2 x #150 | HCE | MECB5185505 | ||

| 240 | 50 x 5 | E | 2 x #150 | HCE | MECB5240505 | ||

| 240 | 50 x 6 | E | 2 x #200 | HCE | MECB5240506 | ||

| 300 | 50 x 6 | E | 2 x #250 | HCE | MECB5300506 | ||

| 300 | 50 x 8 | E | 2 x #250 | HCE | MECB5300508 | ||

| 8 dia | 20 x 3 | D | #065 | HCD | MDCB58S203 | ||

| 8 dia | 25 x 2 | D | #065 | HCD | MDCB58S252 | ||

| 8 dia | 25 x 3 | D | #065 | HCD | MDCB58S253 | ||

| 10 dia | 25 x 3 | D | #115 | HCD | MDCB510S253 | ||

| 10 dia | 25 x 4 | D | #150 | HCD | MDCB510S254 | ||

| 10 dia | 25 x 6 | D | #150 | HCD | MDCB510S256 |

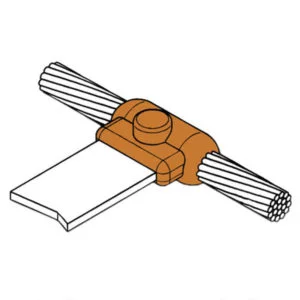

Horizontal Bar Tap to Horizontal Cable Run Tee Joint – CB5 is a cable to bar exothermic welded connection that requires a HCD or HCE Handle Clamp.

The KingsWeld exothermic connection is a permanent,maintenance-free weld that will not loosen overtime or deteriorate with age .There is no increase in resistance in an exothermically weldedconnection, unlike in most pressure type (bolt/crimp) connectionsi.e.copper ground rod or grounding cable attached with ground rod clamps or cable terminal. A kingsWeld weld metal consists of copper oxide, aluminium and flux in a granular (powder) form. Comes in standard sizes.

KingsWeld exothermic mould is manufactured from high quality graphite. This lends itself to easy machining, as well as being able to withstand the high thermal and mechanical shocks produced during the exothermic welding process. Heat obtained in such reactions is in excess of 2000º C.

Our moulds are deisgned to have an average lifetime of 50 to 60 connections. But, if treated with care, it is possible to obtain a significantly longer life.

Graphite is both brittle and soft, therefore it is important that the operator takes care while handling the product. Worn-out or damaged moulds should not be used.

Each mould has a nameplate, detailing the connection type, part code, and the correct weld metal size to be used.

If you do not see the connection, configuration or size of conductor that you require, please contact our sales office who will be pleased to assist you.

To make a KingsWeld connection certain items might be required such as a KingsWeld mould, Handle Clamp, Weld Metal, and/or Flint Gun.Mould Care Guide: KingsWeld moulds are manufactured from high quality graphite which, by nature, is soft and needs to be handled with care in order to get the maximum lifetime.

Mould Inspection: